- The Steel & Alloys Expert

- Mumbai,Maharashtra

- naresh@diamondalloysinc.com

- +91 9619770065

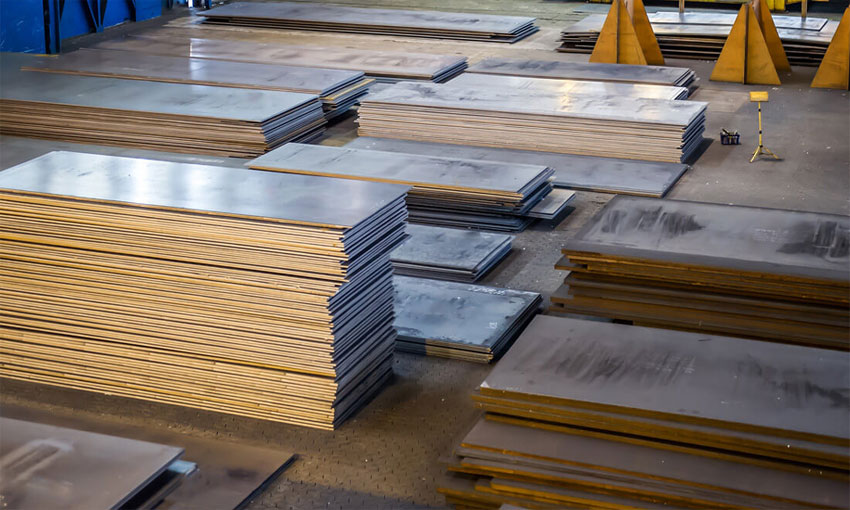

We here at the Diamond Alloys are working for ages to make the world the best place to live. Our company looks after every kind of products of our field and constantly keep working for the improvement an enhancement of the quality and the working ability of the product which makes us much more demanding and perfect in our industries. The kinds of DSQ Plates designed and fabricated by our company is constructed while keeping in mind the experience that we need our customers to experience and make our companies quality and image in their mindset. It is suggested that the plates ought to be scrubbed cautiously after printing. Undeviating disclosure to daylight, ozone and warmth should be circumvented.

These kinds of DSQ plates are being circulated by several provider and suppliers in the extensive variety; these kinds of product are supplied by us comes in different types of dimensions and various sizes. These types of plates are supplied by our company are perfect in order to satisfy the various needs of the customers. These kinds of plates fabricated by our company are of great demand and highly admired for their dynamic edifice, free from any kind of corrosive activities, highly repellent to every kind of erosive effect or action, and tolerance of the products designed by our company regarding any kind of distortion occurred by nature along with numerous and enormous kinds of characteristics as well.

These kinds of DSQ Plates fabricated by our company is made by the help of the perfect balance of some highly qualified engineers, professionals who have numerous years of experience in the manufacturing sectors, not easily attainable kind of raw materials and fully automated modernized machinery. This perfect blend makes a top-notch quality DSQ (Deep Soft Quality) plates. These kinds of plates are highly applicable to various different kinds of applications. These kinds of alloy plates consist of different kinds of chemical materials and elements. The chemical compositions of these plates manufactured by our company consists of carbon, phosphorous, silicon sulphur, manganese and some minimal amount of different other kinds of elements.

These kinds of plates are even made easily obtainable to the people in the market in the desired quantity and quality of the customers. Our companies fabricated plates are available for the betterment of the betterment of various industries in accordance with their work. These kinds of DSQ Plates are hugely used in various sectors of different kinds of industries. There is a huge demand in the industrial sectors for the kinds of deep soft quality plates designed by our company, as the product of our company is constructed by the top-notch quality raw materials. These kinds of plates provide you with a damage-free black mask layer.

The applications in which these kinds of DSQ Plates are primarily galvanizing, thermal power stations, slide conveyor, gas and steam turbines, boiler and heat exchanger, some parts of liquefied petroleum and chemical industries. Some other uses of these kinds of plates produced by our company are pharmaceuticals, sea water equipment’s and in some parts of offshore oil drilling companies.

The testing process of the DSQ Plates consists of some of the various different kinds of severe strict quality test in accordance with the international quality standards. We need to be ensured about the quality of the product provided to the test reports are provided along with the product. Some of the tests performed are hardness test, positive material test, intergranular corrosion test, flattening test, flaring test and many more. The product is wrapped in bubble wrap polybags or gunny bags and then kept inside the wooden boxes, pallets or cartons.

| Item | DSQ (Dead Soft Quality) |

|---|---|

| Thickness | 5mm-150mm |

| Width | 1000mm-4500mm |

| Length | 3000mm-18000mm |

| Process | Hot-Rolled (HR) |

| C | Mn | P | Si | S |

| 0.04 - 0.06 | 0.230 - 0.025 | 0.021 - 0.027 | 0.021 - 0.027 | 0.037 - 0.050 |

| Yield Strength (MPa min) | Ultimate Tensile Strength (MPa min) | %Elongation (min) |

| 245 | 375 | 25 |