- The Steel & Alloys Expert

- Mumbai,Maharashtra

- naresh@diamondalloysinc.com

- +91 9619770065

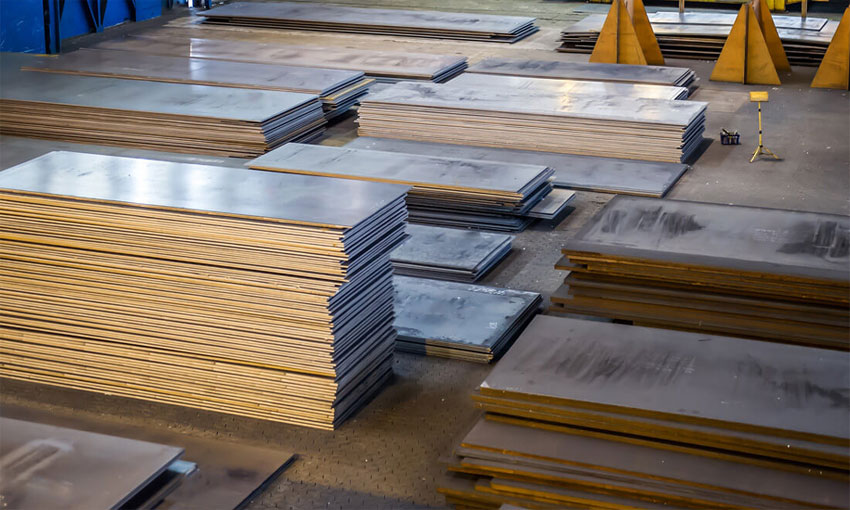

Diamond Alloys is one of the largest stockholder and stockiest of STRUCTURAL & OFFSHORE STEEL EN 10025-2 PLATES across the world. The plate is the European Standard BS EN 10025 series that offers excellent qualities and are used in further processing of plates of non-alloy quality. The industry use efficient quality of raw materials in the manufacturing process of these plates. Besides, they have a specialization in offering good quality of Offshore and Structural Steel plates.

Characteristics found in this plate are excellent resistance property, low phosphorus and sulfur content, good weldability in extensive temperature, excellent resistance to acidic environment and good toughness are some of the properties.

The industry is specialized in offering the exclusive range and characteristics of Offshore and structured steel plates that are in high quality and low cost. They use finest quality raw material which are procured from the reliable market vendors which are further quality tested by the industry professionals. Diamond Alloys offers the plates in customized shapes, size and thickness as per the necessity of the regarded buyers.

Talking about the stock supply services offered by the industry, the plates are design and fabricated as per the necessity of the buyers. The industry supplies manufactured Structural plates in stock to their buyers across the world.

While manufacturing STRUCTURAL & OFFSHORE STEEL EN 10025-2 PLATES, the industry use finest quality of raw material which is further quality tested by the industry professionals. The manufacturing of the plates is performed under the strict guidance of the trained industry professionals. Moreover, the industry use modern machinery and other inventory technology in order to enhance the productivity and efficiency of the plates. At Diamond Alloys, the industry is committed in offering complete customer satisfaction when it comes to quality, performance and durability of the product.

There are several material tests conducted on EN 10025-2 STRUCTURAL & OFFSHORE STEEL PLATES in order to ensure its strict quality and efficiency before finally delivering it to the customers. material tests such as mechanical test, hardness test, positive material identification test, intergranular corrosion test, flaring test, flattening test, micro and macro test, eddy current test, pitting resistance test and chemical analysis are some of the tests performed by the professionals.

The industry is committed in offering tests certifications to the clients along with the Structural and Offshore steel plates. Manufacturer TC in conformance with EN 10204, raw material report, third party inspection report, radiography test reports and other tests certifications are offered by the industry to their clients.

In order to ensure the quality of the plates is preserved or not, the industry use efficient packaging methods. The EN 10025 series plates are wrapped in poly bags and then packed in large wooden cases, crates or pallets that are free from fumigation and other impurities. Moreover, the sales representative of the industry briefs with the clients and completes all the documents formalities when shipping the product out of India. Also, the industry offers relevant shipping documents along with the product.

There are several documents offered by the industry to the clients along with the STRUCTURAL & OFFSHORE STEEL PLATES EN 10025-2 PLATES. These documents helps the clients to counterpart the products with the offered documents. Documents such as fumigation certifications, welding procedure specification, packaging list that includes the net and the gross weight, guarantee letter, commercial invoice, certificate of origin, and lab reports are some of the documents offered by the industry along with the product. Documents help in maintaining complete transparency with the buyers when exporting the product.

| Item | Offshore & Structural Steel Plate |

|---|---|

| Thickness | 5mm-150mm |

| Width | 1000mm-4500mm |

| Length | 3000mm-18000mm or as custom’s request |

| Technique | hot rolled |

| Standard | EN 10025-2:2004 |